Introduction

People

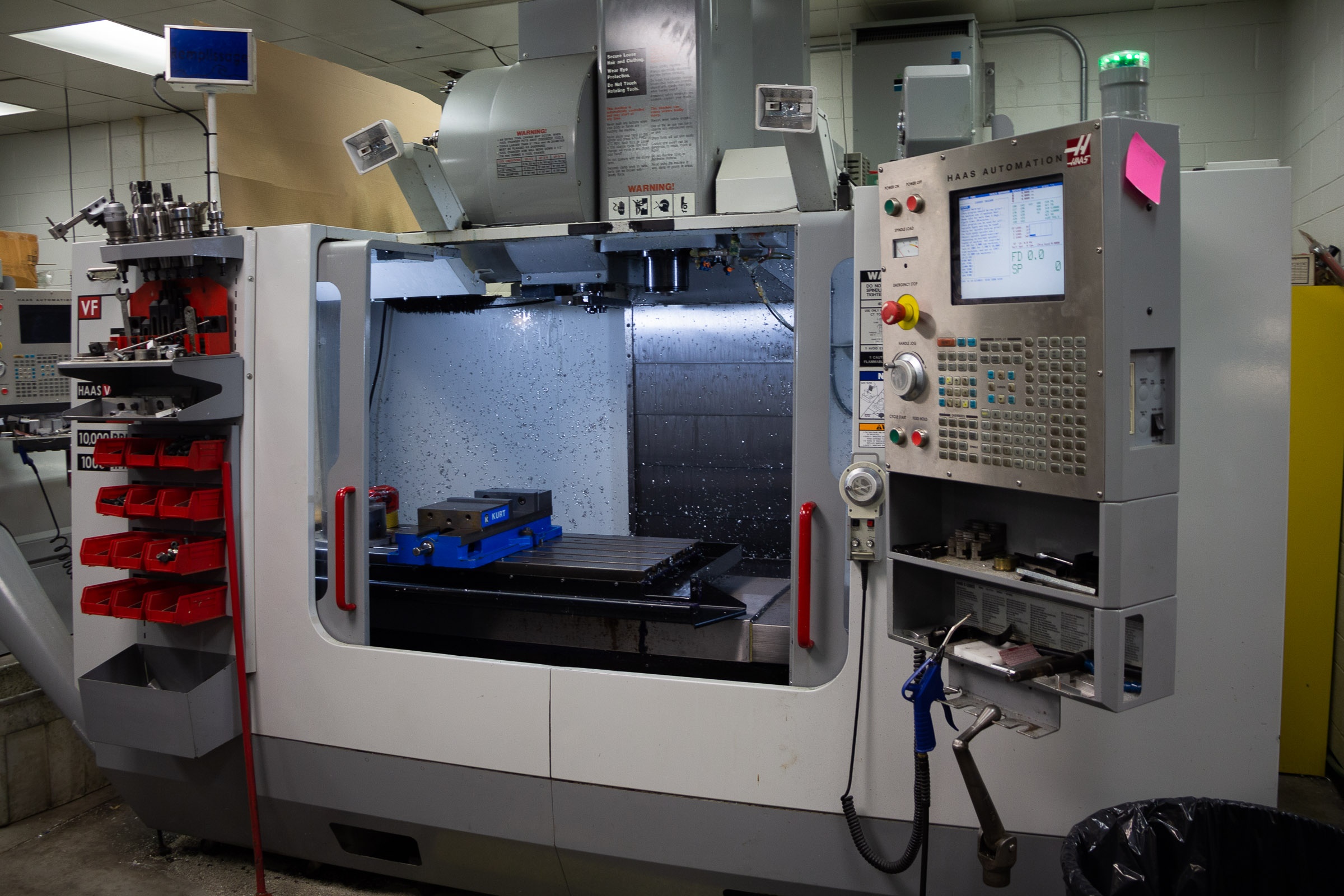

Equipment

The machine shop is very well equipped for small to quite large prototypes or custom builds. It has conventional and CNC tools, sheet metal tools, welding tools, 3D printers and more. Here is a list of our machines and the maximum sizes they can accept:

- CNC milling

- HAAS VF-3

- 4-axis

- 40" X x 20" Y x 25" Z

- HAAS VF-3

- CNC lathe

- HAAS SL-30

- 21" D x 32" L

- HAAS SL-30

- Milling

- First LC-205VHDX

- 33" X x 17" Y x 17"

- Vertical and horizontal spindles

- Maximart MX-B5S

- 47" X x 23" Y x 24" Z

- First LC-205VHDX

- Lathe

- Cyclematic CTL-618EVS

- 11" D x 18" L

- Microweily TY-1640-S

- 16" D x 40" L

- Microweily TY-1860-TS

- 18" D x 60" L

- SDG Type 22

- 22" D X 144" L

- Cyclematic CTL-618EVS

- Drill press

- Arfa RF-40S2F

- Bandsaw

- Do-All C-916

- Horizontal

- Do-All DBW-1A

- Vertical

- Do-All C-916

- Welder

- TIG

- Miller Dynasty 400

- MIG

- Lincoln Electric Power MIG255

- Stick

- TIG

- Plasma

- ESAB Powercut 1500

- Spot welder

- Up to 24" away from sides

- Weld passivation

- Walter Surfox 203

- Oven

- Pyradia F300 H

- 1200°C

- 16" x 16" x 13"

- Pyradia 200HPBI

- 1400°C

- 12" x 12" x 9"

- Pyradia F300 H

- Sand blaster

- 18" x 22" x 42"

- Hydraulic press

- 3 tons

- 20" H

- 10 tons

- 46" H

- 3 tons

- Punch

- Small Woodshop

- Roller

- 23" L x 1/8" T

- Waterjet

- Wazer

- 12" x 18"

- SS 3/16", Aluminum ½", HDPE 5/8", carbon fiber ¼", rubber ¾", foam 1", glass ¾", ...

- Wazer

- Laser engraver/cutter

- BossLaser HP-3655

- 150W CO2 laser

- 36" x 55" with 4 side feedthrough

- Metal up to gauge 18

- Plastics up to ½"

- Foam, fiber glass, rubber, wood, ...

- BossLaser HP-3655

- 3D printers

- Formlab 3BL - Wash L - Cure L

- SLA

- 13" x 8" x 12"

- Proprietary resins

- Bambulab A1 with AMS

- FFF

- 10" x 10" x 10"

- PLA, PETG, TPU, ...

- Creatbot PEEK-300

- FFF, dual head

- 12" x 12" x 16"

- PLA, ABS, PC, Nylon, PETG, Carbon Fiber, PEI, PEEK, ...

- Formlab 3BL - Wash L - Cure L

- Sheer

- Durma RGM2504

- 100" W x 5/32" T

- Break

- Sampson

- 73" L

- Sampson

Exemples de projets actuels et passés

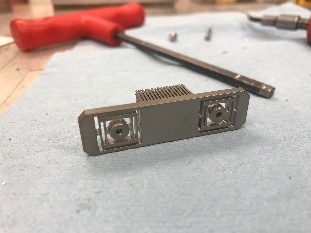

- ATLAS ITk Tracker Upgrade: The machine shop has supported the Carleton group in the R&D, prototyping, production and testing of the ITk thin silicon microstrip sensors. The machine shop has built the “cold chuck” that can hold the sensor in place using vacuum and provide all the electrical and signal interfaces to bias the sensor and readout the associated leakage current. The TK-jig design and fabrication quality made it the standard test stand used by the entire ITk strip project with TK-jig prototypes fabricated by the Resource shipped to six collaborating ITk labs in Europe and North America.

- Barium tagging for neutrinoless-double-beta-decays: The Ba ion tagging R&D program in Canada aims at developing an efficient experimental method for extracting, transporting and detecting single ions from a liquid xenon (LXe) TPC such as nEXO.The UdeM shop has constructed several apparatus for that research program, such as parts of the multi-reflection time-of-flight mass spectrometer, quadrupole mass filter and a linear Paul trap for laser fluorescence spectroscopy.

- Hyper-K neutrino experiment: Hyper-K is a next generation neutrino oscillation experiment aiming at measuring CP violation in the neutrino sector. The UdeM machine shop has played an important role in assisting the development of various mPMT prototypes for Hyper-K, such as manufacturing stainless steel back plates with fine machined features.

- nEXO experiment at SNOLAB: The UdeM machine shop has assisted the EXO/nEXO Canadians collaborators. Recent projects include the manufacturing of an installation jig for the source guide tube of the calibration system, as well as complex source storage cassettes that each include a sprocket for source deployment in EXO-200. Also, inline xenon-radon traps were built by the Resource for the R&D of the radon removal system.

- PICO dark matter experiment: The UdeM machine shop has built several part of the various generations of PICO experiments. One notable example is a key custom pressure feedthrough for PICO-40L that had been commercially purchased but failed due to the manufacturer’s inability to conform to the tolerances of the complex component. The UdeM machine shop was able to produce a replacement component in short order, saving months of delay.

- SBC dark matter experiment: The UdeM shop is building part of that future dark matter experiments. It fabricated custom plumbing for the very complicated gas system. The machine shop will build the detectors’ position sensors, SiPM support structure, LED rings and the welding of the central bellows assembly, a task that no other university shop in Canada was able to complete for the SBC collaboration.

Costs

To understand how charges applies, please look at the table below. It will depend on the client's affiliation and what type of work is required. Material can be provided by the client or by the shop. Taxes applies on everything but time. Shop fee includes tool wear, cutting oils, ... Consumable consist of broken tools, tools that we don't have, ...

| Client | Material | Machining/Design time | Shop fee* | Consumable |

|---|---|---|---|---|

| UdeM Physics | Market price | Free | 20$/h | Market price |

| LTA MRS co-applicants | Market price | Free | 0$ | Market price |

UdeM Neuroscience | Market price | Free | 20$/h | Market price |

| UdeM, PolyMtl | Market price | 85$/h | 20$/h | Market price |

| Academic | Market price | 110$/h | 20$/h | Market price |

| Industry | Market price | 150$/h | 20$/h | Market price |

*Shop fee can be a maximum of 20$/h, but often can be less depending on the job.

Contact

The shop is located in the Laboratoire René J.-A. Lévesque on the main campus of Université de Montréal. The address is

- 2905 chemin des Services

- Laboratoire René J.-A. Lévesque, local 157

- Montréal, Qc

- H3T 1J4

You can join our team by phone 514-343-6111 #6221 or by e-mail at atelierlta@phys.umontreal.ca