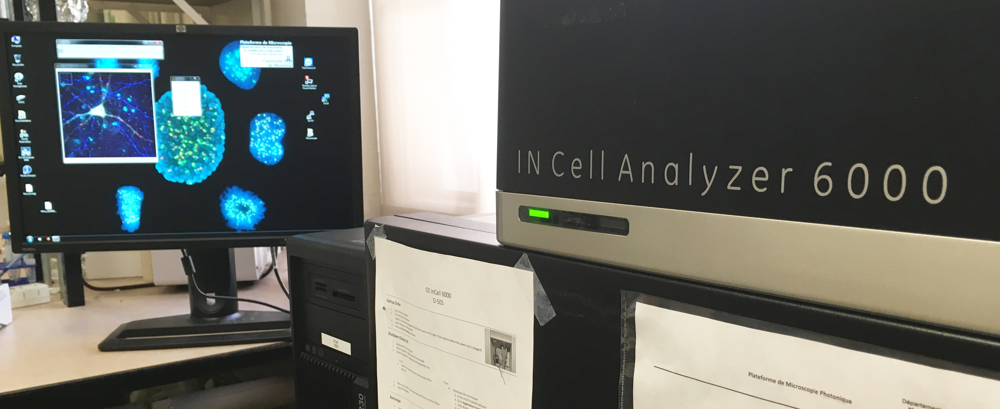

GE InCell Analyzer 6000 High content microscope

JA Bombardier Building, Room 3129

Advanced Microscope Tier 2 usage price

Instrument awarded to Dr. Steve Michnick by the Canadian Foundation for Innovation (CFI # 33122) in 2015

Applications

- Inverted microscope

- Widefield imaging

- Brightfield

- Pseudo phase contrast and DIC

- Fluorescence

- Swept-field imaging

- Fluorescence

- High-throughput imaging

Description

Light sources

LED for transmitted light

Toptica iChrome MLE for fluorescence

Objectives

- 10x/0.45

- 20x/0.75

- 40x/0.6

- 60x/0.95

Filters

DAPI

GFP

Cy3

Cy5

- Cy5.5

Detector

- PCO.edge 5.5

User Guide

Manuals

Log

Technical Datasheet

Instrument Serial W24318-1493815 BK02029

Service Password apiAWL

Workstation

- HP Z230 Workstation Serial

- I139539-CIB

- Motherboard HP 1905 Chipset Intel C226

- BIOS L51 v01.62 v03.61 2019-10-06

- Processor Intel Core i7-4790 3.6 GHz

- RAM 16 GB (4 x 16 GB) DDR3 600 MHz

Drives

- OS 1 TB SSD at 530 MB/s

- Data Storage 2 TB at 170 MB/s (2 x 1 TB spanned volume)

- Video Card integrated Intel HD Graphics 4600

Monitor

HP Zr 24w 24" 1920 x 1200

- OS Windows 11 23H2

GE InCell ANalyzer 6000 v7.2 License files for temperature, transmitted light